Understanding the Functions of Hydraulic Double-Acting Gate Valve

Hydraulic double-acting gate valves are an important component in a variety of industrial and commercial applications. These valves play a vital role in controlling the flow of liquids and gases in various systems. Understanding how these valves work is critical to ensuring their proper operation and maintenance.

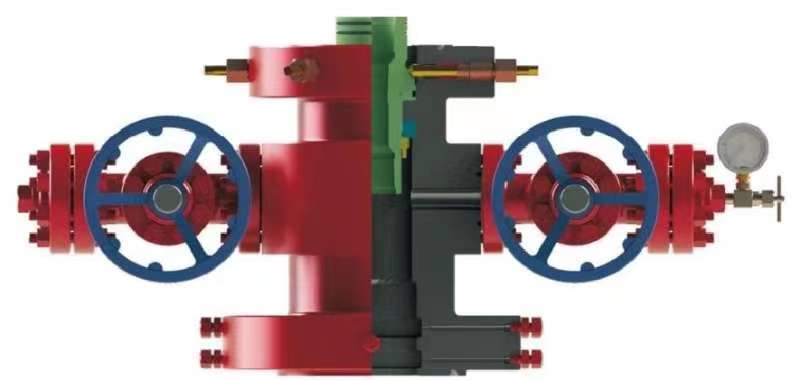

Hydraulic double-acting gate valves are designed to control the flow of fluids by using a gate or wedge that moves up and down to open and close the valve. The double-acting feature allows the valve to operate in both directions, providing greater flexibility and control of fluid flow.

Operation of a hydraulic double-acting gate valve begins with the application of hydraulic pressure to the actuator. The actuator moves the gate or wedge within the valve body. When hydraulic pressure is applied, the actuator moves the gate upward, allowing fluid to flow through the valve. Instead, when hydraulic pressure is released, the actuator moves the gate downward, closing the valve and stopping the flow of fluid.

One of the key components of a hydraulic double-acting gate valve is the hydraulic system that powers the actuator. The system usually consists of a hydraulic pump, hydraulic oil, control valves and hydraulic pipelines. When the control valve is activated, the hydraulic pump pressurizes the hydraulic oil, which is then directed to the actuator to move the gate as needed.

Hydraulic double-acting gate valves are designed to precisely control the flow of fluids. By adjusting the hydraulic pressure and gate position, the flow rate can be precisely adjusted to meet the specific requirements of the system. This level of control is critical for applications where precise flow management is critical, such as industrial processes and fluid distribution systems.

In addition to their precise control capabilities, hydraulic double-acting gate valves are known for their reliability and durability. The robust construction of these valves combined with the hydraulic actuation system ensures that they can withstand high pressures and harsh working conditions. This makes them suitable for use in harsh environments where other types of valves may not operate effectively.

Proper maintenance and regular inspections are essential to ensure the continued functionality of your hydraulic double-acting gate valve. This includes monitoring hydraulic systems for leaks, checking the condition of actuators and gates, and ensuring all components are properly lubricated and free of debris. By following a comprehensive maintenance plan, the life and performance of these valves can be maximized.

In summary, hydraulic double-acting gate valves play a vital role in controlling fluid flow in various industrial and commercial applications. Their ability to provide precise control, reliability, and durability make them an essential component of fluid management systems. Understanding the functions of these valves is critical to ensuring their proper operation and maintenance, ultimately helping to increase the efficiency and effectiveness of the systems in which they are used.