Understanding the functions of choke valves in well control equipment

In well control equipment, choke valves play a vital role in regulating fluid flow in oil and gas wells. These valves are designed to control the pressure and flow of fluids, ensuring the safety and efficiency of drilling operations. In this blog, we’ll take a closer look at how choke valves work and their significance in well control equipment.

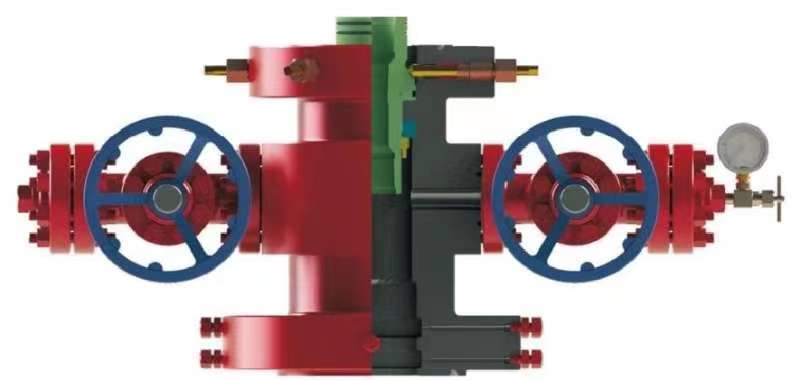

Choke valves are typically mounted on the Christmas tree, a wellhead component that provides control and access to the wellbore. The primary function of a choke valve is to limit the flow of fluid in an oil well, thereby controlling pressure and preventing any potential blowout or uncontrolled release of hydrocarbons. This is especially important during drilling, completion and production operations, where fluid pressure and flow rates need to be carefully managed to ensure personnel safety and well integrity.

The working principle of a throttle valve involves the use of an adjustable orifice to regulate the flow of fluid. By adjusting the valve's opening, operators can control the flow and pressure of fluid to precisely manage wellbore conditions. A choke valve can be manually operated or equipped with automatic controls, depending on the specific requirements of the well and drilling operation.

In addition to controlling fluid flow, choke valves also play a key role in managing well backpressure. During certain operations, such as well testing or production, a specific backpressure must be maintained to optimize fluid flow and ensure reservoir integrity. Throttle valves help achieve and maintain the required back pressure for efficient production and reservoir management.

In addition, choke valves are designed to withstand the harsh conditions encountered during well control operations. They are made of high-strength materials and equipped with seals and packing to ensure reliable performance in high-pressure and high-temperature environments. This rugged construction is critical to ensuring the safety and integrity of well control equipment, especially during critical operations such as well control and blowout prevention.

In summary, choke valves are an important part of well control equipment and play a vital role in regulating fluid flow and managing oil and gas well pressure. Their ability to control flow, backpressure and fluid dynamics is critical to ensuring the safety and efficiency of drilling, completion and production operations. Understanding the workings and importance of choke valves is crucial for any player in the oil and gas industry as they are vital to maintaining the integrity of the well and ensuring the success of drilling operations.