Understanding the Functions of Casing Head Assemblies in Wellhead Equipment

In oil and gas well operations, casing head assemblies play a vital role in ensuring the safety and efficiency of the production process. This important component of wellhead equipment is designed to provide support for the casing string and seal the annulus between the casing and the wellbore. Understanding how casing head assembly work is critical for anyone in the oil and gas industry.

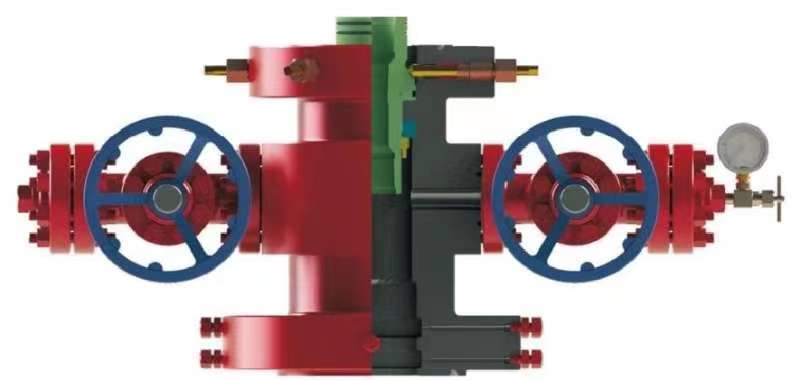

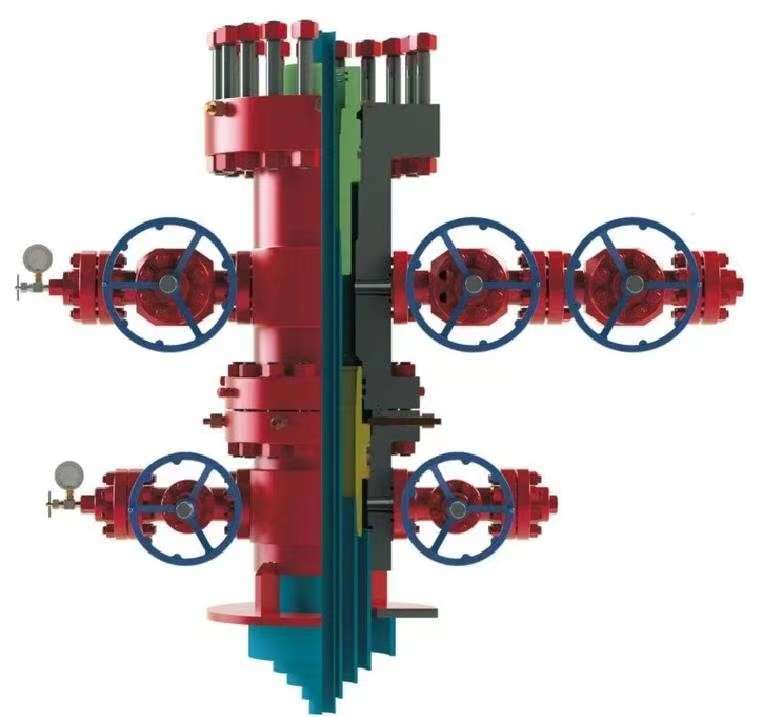

The casing head assembly is typically installed on top of the well casing and serves as the connection point for various components of the wellhead equipment. It consists of several key components, including the casing head, casing spool and casing hanger. The casing head is a large, heavy-duty component that is bolted to the top of the well casing. It provides housing for the casing spool and serves as support for the weight of the casing string.

A casing spool, on the other hand, is a cylindrical device that is bolted to the top of the casing head. It provides a means of securing the casing hanger and creating a seal between the casing and the wellhead. The casing hanger is a critical component that supports the weight of the casing string and provides a seal to prevent fluids from escaping the well.

One of the primary functions of the casing head assembly is to provide a safe and reliable connection between the casing string and the wellhead. This connection is critical to maintaining the integrity of the well and preventing leaks of oil, natural gas or other fluids. The casing head assembly also provides a means of suspending the casing string within the wellbore and allows for the installation of other important components such as blowout preventers and production trees.

In addition to providing support for the casing string, the casing head assembly also plays a vital role in the cementing process. After the casing string is installed, cement is pumped into the annulus between the casing and the wellbore to create a safety barrier and prevent fluids from migrating between different geological formations. The casing head assembly provides a means of injecting cement slurry into the annulus and ensures that the cement slurry is evenly distributed around the casing string.

Additionally, casing head assemblies are designed to accommodate the installation of various types of wellhead equipment, such as valves, chokes, and pressure gauges. These components are critical for controlling the flow of fluids in the well and monitoring downhole pressure and temperature conditions. The casing head assembly provides a safe and accessible location for the installation of this equipment, allowing for safe and efficient well operation.

To sum up, the casing head assembly is a key component of wellhead equipment and plays a vital role in the safe and efficient operation of oil and gas wells. Casing head assemblies ensure well integrity and productivity by providing support for the casing string, creating a seal between the casing and wellhead, and accommodating the installation of critical wellhead equipment. Understanding how casing head assemblies work is critical for anyone involved in the design, construction or operation of oil and gas wells.