Understanding the Function of Tubing Heads in Wellhead Equipment

In oil and gas well operations, wellhead equipment plays a vital role in ensuring the safe and efficient extraction of resources from the surface. The tubing head is an important part of the wellhead equipment and is the key interface between the wellbore and surface production equipment. In this blog, we’ll take a closer look at the function of tubing heads in wellhead equipment and explore how they contribute to the overall operation of an oil and gas well.

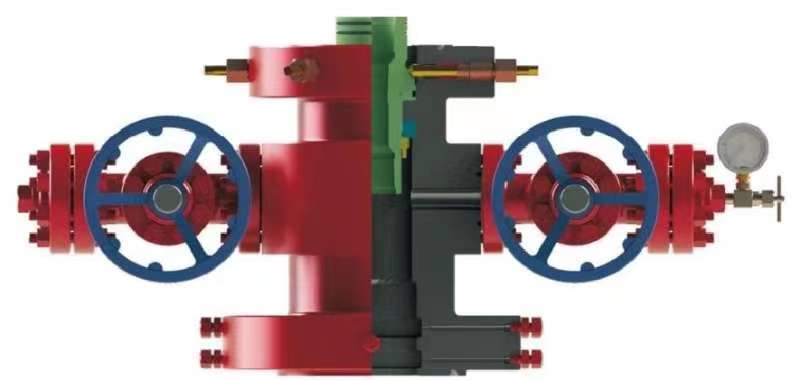

The tubing head is an integral part of the wellhead assembly that provides the connection point for the production tubing to transport extracted fluids from the wellbore to the surface. The primary function of the tubing head is to support the weight of the production tubing and provide a seal to prevent fluid and gas from escaping from the wellbore. Additionally, tubing heads are designed to accommodate a variety of workover activities, such as installation of downhole tools, production logging, and well maintenance operations.

Tubing head designs are customized to the specific requirements of each well, taking into account factors such as well depth, pressure and production characteristics. Tubing heads are usually equipped with a series of outlets and connections to facilitate the installation of valves, restrictors and other production equipment. This controls and regulates fluid flow from the wellbore to the production facility, ensuring safe and efficient operations.

One of the primary features of the tubing head is to provide a secondary seal, which is critical to containing wellbore fluids and preventing environmental contamination. These secondary seals are designed to withstand high pressures and temperatures, providing an extra layer of protection against potential leaks or blowouts. In the event of a well control incident, secondary seals in the tubing head play a critical role in controlling wellbore fluids and preventing the release of hydrocarbons to the environment.

The tubing head is also equipped with hangers, which are mechanical devices that support the weight of the production tubing and provide a secure connection to the wellhead. The hanger is designed to withstand the forces exerted by the production tubing, ensuring it remains in place and effectively seals the wellbore. In addition, tubing heads can incorporate features such as locking screws and locking profiles to further secure production tubing in place, providing additional security and reliability.

In summary, the tubing head is an important part of the wellhead equipment, serving as the interface between the wellbore and surface production facilities. Their primary functions are to support production tubing, provide seals to contain wellbore fluids, and facilitate the installation of production equipment. With their rugged design and critical safety features, tubing heads play a vital role in ensuring safe and efficient operation of oil and gas wells.