Understanding the Function of Surface Safety Valves as Important Well Testing Equipment

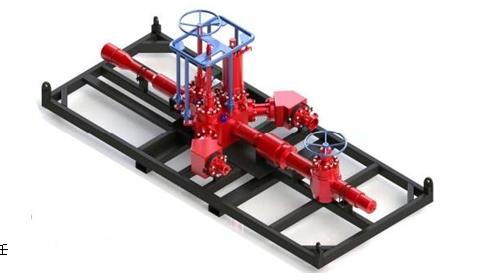

For the oil and gas industry, safety and efficiency are of paramount importance. Well testing equipment is an important part of the exploration and production process, and the equipment used must meet strict safety standards. One such piece of equipment is the Surface Safety Valve (SSV), which plays a key role in ensuring the safety and integrity of well testing operations.

So, how does the surface safety valve function as an important well testing equipment? Let’s delve into the functionality and importance of SSV in well testing.

Surface safety valves are designed to provide a fail-safe mechanism to control fluid flow from the wellhead. In the event of an emergency or abnormal operating conditions, the SSV can be activated to quickly shut down flow, preventing potential hazards such as a blowout or uncontrolled release of hydrocarbons. This capability is especially important during well testing operations because pressures and flows can vary greatly.

Operation of surface safety valve is typically controlled remotely via a central control panel, allowing operators to monitor and intervene in real time when necessary. The valve is equipped with sensors and actuators that respond to changes in pressure, temperature and other relevant parameters, allowing it to act quickly and decisively when needed.

During well testing, SSVs are an important component in maintaining well integrity and ensuring the safety of personnel and equipment. It provides a means of isolating the wellbore from surface facilities, allowing reservoir fluids to be safely contained and controlled. This is especially important during the initial flowback and cleanup phases of well testing, where the behavior and characteristics of the well are evaluated.

In addition to their safety functions, surface safety valves also serve to optimize the efficiency of well testing operations. By providing a means to control fluid flow, SSV enables precise measurement and sampling of reservoir fluids, which is critical for assessing a well's productivity and characteristics. This data is critical for making informed decisions about future development and production strategies for wells.

Additionally, SSV helps improve the overall reliability and integrity of the well testing process. Its ability to quickly respond to abnormal conditions and shut down flow helps minimize the risk of equipment damage and environmental impact. This in turn reduces downtime and operational disruptions, ensuring well testing operations run smoothly and safely.

To sum up, the surface safety valve is a key component of well testing equipment and plays a key role in ensuring the safety, efficiency and integrity of well testing operations. Its ability to provide fail-safe control of fluid flow, coupled with remote operation and monitoring capabilities, makes it an indispensable asset for the oil and gas industry. By understanding the function and importance of SSVs, operators and stakeholders can understand the important role they play in the well testing process and the broader context of safe and responsible resource extraction.