Understand the functions of mud and gas separators in well control equipment

Among well control equipment, mud gas separators play a vital role in ensuring the safety and efficiency of drilling operations. This important piece of equipment is designed to separate and remove gases from drilling mud, preventing potential hazards and maintaining the integrity of the drilling process. In this blog, we’ll take a closer look at the inner workings of a mud gas separator and explore how it contributes to the overall well control system.

The primary function of a mud gas separator is to remove gases, such as methane, from the drilling mud that returns to the surface during drilling. As drilling proceeds, the formation of air pockets within the wellbore causes gas to flow into the drilling mud. If left unchecked, this can lead to a variety of problems, including kicking injuries, blowouts, and other dangerous situations. Mud gas separators effectively mitigate these risks by separating the gas from the mud, allowing the mud to be safely disposed of or recycled, while containing the gas for further processing.

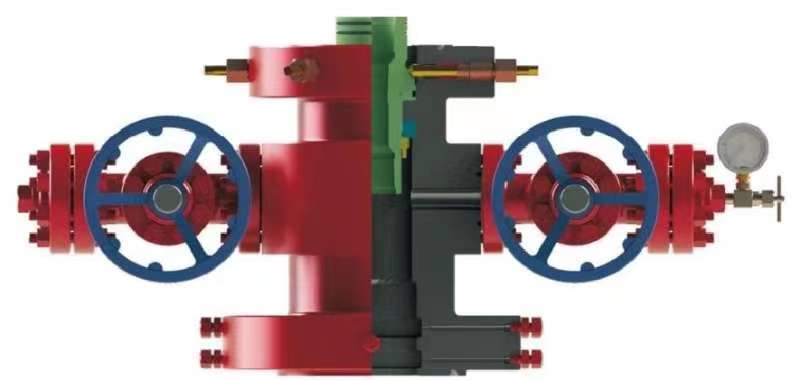

So, how does a mud gas separator work? The process begins when gas-filled drilling mud enters the separator at high velocity, usually through a tangential inlet. This causes the slurry to rotate within the separator, creating centrifugal force that helps separate gas from liquid. Lighter gases rise to the top of the separator and are discharged through the gas outlet, while heavier drilling mud is directed to the bottom for further processing.

One of the key components of a slurry gas separator is the exhaust line, which safely releases the separated gases to the atmosphere or directs them to a flare system for controlled combustion. This is an important safety feature as it prevents the accumulation of gas within the drilling area, reducing the risk of fires and potential hazards to personnel and equipment.

In addition to its primary function of gas separation, the mud gas separator also serves as a key indicator of wellbore condition. By monitoring gas levels in drilling mud, operators can gain insight into the presence of hydrocarbons and other formation fluids, allowing them to take proactive well control measures. This real-time data helps prevent well control incidents and maintain the overall integrity of drilling operations.

In summary, the mud gas separator is an indispensable component of well control equipment and plays a vital role in the safe and efficient management of drilling operations. By effectively separating gas from drilling mud and providing valuable insights into wellbore conditions, mud gas separators contribute to the overall safety and success of drilling projects. Understanding its function and importance is critical for all those involved in well control operations to ensure that drilling activities are conducted with the highest standards of safety and environmental responsibility.