The functions of ground test trees and flow control heads in ground test products

Surface testing products play a vital role in the oil and gas industry, enabling efficient extraction and management of resources. Two key components of these products are the ground test tree and the flow control head, which work together to ensure smooth, safe operation of the ground test equipment. In this blog, we’ll take a closer look at the capabilities of these components and explore how they can improve the overall efficiency of your surface testing product.

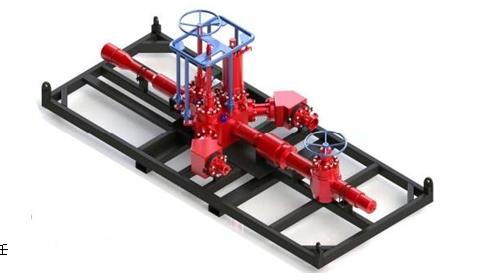

The surface test tree is an important interface between the wellhead and surface test equipment. It is designed to provide control and monitoring capabilities during testing. The primary function of the surface test tree is to regulate fluid flow from the well, thereby collecting valuable data and evaluating reservoir performance. In addition, ground test trees facilitate safe well shut-in in emergency situations, ensuring the protection of personnel and equipment.

One of the main features of the above-ground test tree is its ability to accommodate various types of valves and throttles, allowing precise control of the flow of fluids. This flexibility is critical to adapt to different well conditions and optimize the testing process. In addition, the surface test tree is equipped with pressure gauges and sensors that provide real-time data on well performance, allowing operators to make informed decisions regarding production and reservoir management.

The flow control head is complementary to the surface test tree and is responsible for managing fluid flow from the well to the surface test equipment. The flow control head is designed to withstand high pressures and temperatures, ensuring reliable, safe operation in demanding oil well environments. By combining valves, restrictors and other controls, flow control heads enable operators to regulate the flow and pressure of produced fluids, allowing for precise testing and data collection.

In addition to its flow regulation function, the flow control head also acts as a barrier against potential well control issues such as kicks and blowouts. Its rugged construction and advanced control features provide a critical layer of protection, protecting the well and surrounding environment from unexpected events. In addition, the design of the flow control head facilitates the installation and recovery of downhole tools and improves the efficiency of well testing operations.

The integration of surface test trees and flow control heads into surface test products represents a sophisticated approach to well testing and reservoir management. By combining these components, operators can effectively control the flow of fluids, monitor well performance and ensure the safety of personnel and equipment. The seamless interaction between the ground test tree and the flow control head demonstrates the industry's commitment to innovation and operational excellence in ground test operations.

In summary, surface testing trees and flow control heads play an integral role in the functionality of surface testing products, allowing operators to conduct well testing operations efficiently and safely. Their ability to regulate flow, monitor performance and reduce risk highlights their importance in the oil and gas industry. As technology continues to advance, these components will undoubtedly continue to evolve to meet the changing needs of surface testing, further enhancing the industry's capabilities in resource extraction and reservoir management.